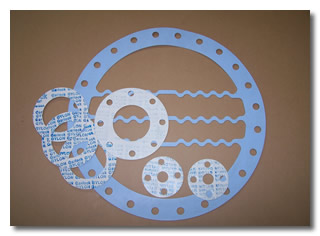

Gylon® Gaskets

Hennig Gasket & Seals is a leading manufacturer of high quality Gylon Gaskets for a wide range of industries across the country. No matter if your project calls for a single prototype or large production runs; no matter if the gylon gasket is simple or complex, we are committed to our promise of providing our customers with non-metallic material that has been accurately cut to the tightest tolerance and delivered with the quickest turnaround in the industry. That has been our promise for over 100 years.

Hennig Gasket & Seals will custom manufacture your gylon gasket from provided blueprints or will reverse engineer a sample part for all critical dimensions. Our proven manufacturing techniques (which include waterjet cutting, flash cutting and die cutting) will deliver on-time, on-budget parts that are precision engineered to your exact specifications. Guaranteed.

Gylon® Gasket Benefits:

GYLON®, a product of Garlock Sealing Technologies, is a reinforced PTFE gasket material that exhibits significantly reduced creep relaxation, along with outstanding chemical resistance. It is not recommended to reuse a gasket. A gasket's function is to conform to flange high and low spots when compressed, and its ability to reseal decreases after it is compressed. Gaskets that contain rubber and which have experienced elevated temperatures will be even less likely to reseal. The benefits of a Gylon® Gasket include:

- Highly Resistant to Chemicals - capable of withstanding a broad range of chemicals during extended service periods.

- Tighter Seal - provides superior performance compared to conventional PTFE; ensures reduced emissions and product loss

- Significant Cost Savings - reduces operation costs by minimizing maintenance required; loss of fluids; minimal energy consumption; reduction in waste; lower inventory costs

- Large Sheet Sizes Available - some of the largest sheet sizes available in the industry; this translates to better material utilization (more gaskets and seals per sheet), with less waste material

- Easy installation, easy to cut - GYLON® Style 3540 is perfect for warped, scratched, pitted or wavy flanges.

GYLON® Gasket Material:

Hennig Gasket & Seals is an authorized distributor of Garlock Gylon gasketing material. Our inventory includes:

- GYLON® Style 3500 – (fawn color). PTFE with a silica filler. Industry application: food, power generation, chemical, water and wastewater treatment. Resistent to: water, strong acids (with the exception of hydrofluoric acid), steam, solvents, cryogenics, chlorine and other corrosive applications. This gasket material complies with FDA regulation 21CFR177.1550 and meets ingredient and extract requirements. Style 2500 has USDA approval for direct contact in meat and poultry applications.

- GYLON® Style 3504 – (blue color). PTFE with glass microspheres. Industry application: food, power generation, chemical, water and wastewater treatment. Resistant to: refrigerants, water, moderate acids, solvents, cryogenics, hydrocarbons. This material complies with FDA regulation 21SFR177.1550 and meets the ingredient and extract requirements. The filler is listed in the Food Chemicals Codes (FCC 3rd Edition) and is considered GRAS (generally recognized as safe - 21CFR170-30).

- GYLON® Style 3510 – (off white color). PTFE with barium sulfate filler. Industry applications: oil and gas, petrochemical, pharmaceutical, water treatment, chemical, power generation, medical. Resistent to: steam, gases, chlorine, water, moderate acids, hydrocarbons, chlorine, cryogenics, and strong caustics. This material complies with FDA regulation 21CFR177.1550 and meets ingredient and extract requirements. The fillers are also acceptable under 21CFR177.2600 and coloring agents (where used) under 21CFR178.3297.

- GYLON® Style 3540 – Microcellular PTFE. Industry applications: chemical, petrochemical, oil and gas. Resistent to: strong acids, chlorine, hydrocarbons, cryogenics, and strong caustics.

- GYLON® Style 3565 – PTFE with glass filler. Industry applications: medical, laboratory, power generation, chemical, petrochemical, oil and gas. Resistent to: solvents, moderate acids, cryogenics, hydrocarbons, glass-lined equipment, and moderate caustics. This material (ENVELON®) complies with FDA regulation 21CFR177.1550 and meets the ingredient and extract requirements. The filler is listed in the Food Chemicals Codes (FCC 3rd Edition) and is considered GRAS (Generally recognized as safe - 21CFR170.30).

Hennig Gasket offers just in time (JIT) delivery of GYLON® gaskets, along with specials and prototypes being fabricated and shipped on the same day. Our in-stock inventory of GYLON® material includes 1/16” and 1/8” thick sheets, measuring 60” by 60”. Request a quote today!